Premium Wood Products for Every Project

HIGH-QUALITY PLYWOOD SINCE 1951 | SHIPPING AVAILABLE NATIONWIDE

Rely on Us for

Time-Tested, Expert Plywood Manufacturing

Buffalo Veneer and Plywood are experts in manufacturing several types of high-quality veneer plywood. We also stock a wide selection of veneer species at all times to meet your needs. Reach out today to learn more.

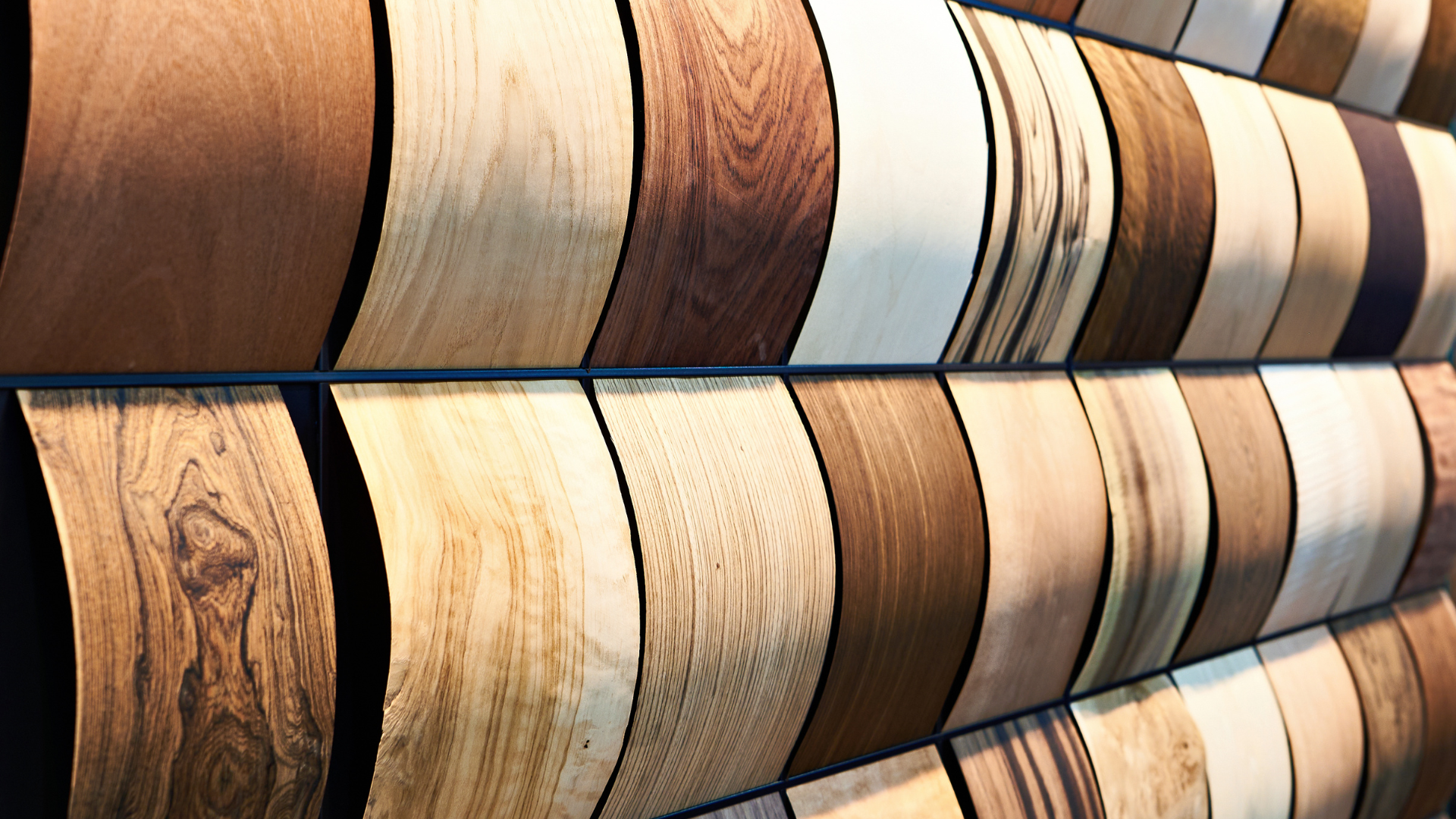

ExpLORE OUR EXTENSIVE SELECTION

Wood Veneer and PANELS AVAILABLE

We are proud to warehouse a variety of veneered panels at all times lumber core, MDF, particle board, and veneer core at all times. We also have a wide variety of inventories of 8-foot and 10-foot veneer species. If you require unlisted species and/or cuts (such as burl, crotch, pommele, etc.), please feel free to inquire.

VeneeRS AVAILABLE

Please note separate inventories for 8- and 10-foot veneers.

Special orders may require minimums.

FACE VENEER SPECIES

Alder (Red): Plain Slice Select, Knotty / Rustic

This wood offers a smooth, even grain, ideal for both select finishes and a more rustic, knotty appearance, making it versatile for various projects.

Anigre: Quarter Slice (Figured)

Known for its beautiful, shimmering grain, Quarter Slice (Figured) Anigre adds a touch of elegance with its unique texture and natural luster.

Ash: Plain Slice White, Plain Slice Natural, Quarter Slice White, Rotary Brown, and Rotary Natural

(available in whole piece upon request)

Ash wood is strong and flexible, available in a variety of cuts from plain to rotary, with colors ranging from creamy white to rich brown. Ideal for both structural and decorative uses.

Bamboo: Edge / Vertical Grain, Flat / Horizontal Grain

Sustainable and eco-friendly, bamboo is available in Edge/Vertical and Flat/Horizontal Grain, offering a sleek and modern aesthetic with natural strength.

Beech (European Steamed): Plain Slice

This warm, reddish wood has a fine, uniform texture, perfect for achieving a polished, refined look in furniture or cabinetry.

Beech (American): Rotary

With its pale color and fine grain, Rotary-cut American Beech is versatile and easy to work with, suitable for a range of interior applications.

Birch: Plain Slice White, Plain Slice Natural, Rotary Natural, Rotary Red, and Rotary White

(available in whole piece upon request)

Strong and resilient, birch wood comes in various shades and cuts, offering everything from pale, clean whites to deeper natural tones, perfect for cabinetry and millwork.

Butternut: Plain Slice

This light, soft wood features a subtle grain and warm, golden-brown color, ideal for fine woodworking projects where a soft touch is needed.

Cedar (Aromatic): Rustic

Known for its distinctive scent and natural resistance to insects, Aromatic Cedar offers a rustic look with practical benefits.

Cedar (Western Red): Plain Slice Clear, Rustic

Lightweight yet durable, Western Red Cedar comes in clear and rustic cuts, perfect for both exterior and interior applications.

Cedar (Spanish): Plain Slice

Spanish Cedar provides a fine texture and smooth finish, making it ideal for high-quality cabinetry and musical instruments.

Cherry: Plain Slice, Quarter Slice, and Rustic

With its rich, warm tones and smooth grain, cherry wood is a favorite for fine furniture, available in various cuts to suit both traditional and modern designs.

Fir (Douglas): Vertical Grain (Quarter Slice)

Vertical Grain Douglas Fir offers a consistent, straight grain and warm, reddish-brown hue, making it a popular choice for doors and windows.

Hickory: Plain Slice Calico, Plain Slice Heart, Plain Slice Sap, and Rustic

Hickory is a tough, dense wood with striking variations in color, available in various cuts that highlight its dramatic grain patterns.

Jatoba: Plain Slice

Also known as Brazilian Cherry, Jatoba is a dense, durable wood with a deep, reddish-brown color, perfect for flooring and furniture.

Mahogany (African): Plain Slice, Quarter Slice Ribbon Stripe

African Mahogany is prized for its reddish-brown color and straight, even grain, offering a rich, luxurious look for high-end projects.

Makore: Please Inquire

This exotic wood features a fine grain and rich, reddish-brown color, often used in high-end furniture and cabinetry. Contact us for availability.

Maple (Hard): Plain Slice, Plain Slice (Figured), Quarter Slice, Rotary Cut Birdseye, Rotary Cut Curly, Rotary Cut White, and Rustic

(available in whole piece upon request)

Known for its strength and durability, hard maple is available in various cuts, including figured and birdseye, offering both beauty and resilience in furniture and flooring.

Maple (Soft): Rotary Cut

Soft maple is versatile and easy to work with, featuring a smooth texture and light color, making it ideal for a wide range of applications.

Oak (Red): Plain Slice, Quarter Slice, Rift Cut, Rotary Cut, Rustic

(available in whole piece upon request)

Red Oak is strong and durable, with a prominent grain and warm tones, making it a classic choice for furniture and flooring.

Oak (White): Plain Slice, Quarter Slice, Rift Cut, and Rustic

White Oak is known for its strength and water resistance, with a light color and attractive grain, perfect for both indoor and outdoor projects.

Pine (White): Plain Slice Clear, Knotty

White Pine offers a light, clean appearance, available in both clear and knotty cuts, making it versatile for various woodworking projects.

Poplar: Rotary Cut (available in whole piece upon request)

Poplar is a lightweight, easy-to-work-with wood, often used for cabinetry and furniture, with a smooth finish and pale color.

Sapele: Please Inquire

Sapele features a fine, interlocked grain and rich, reddish-brown color, often used for high-end cabinetry and musical instruments. Contact us for availability.

Teak (Burmese): Plain Slice

Burmese Teak is prized for its durability and resistance to water, making it ideal for outdoor furniture and marine applications, with a rich, golden-brown hue.

Walnut (Black): Plain Slice, Quarter Slice, and Rustic

Black Walnut is known for its dark, rich color and fine grain, offering a sophisticated look in both rustic and refined cuts.

Wenge: Quarter Slice

Wenge is a dark, dense wood with a distinctive grain, perfect for creating bold, modern designs.

SEND us A MESSAGE

Fill out the form below, and we will be in touch shortly!